The PoleOS™ Company

Introduction

Cyient is a leading global engineering, manufacturing, and digital technology solutions company headquartered in Hyderabad, India. They have leveraged one of the most diverse global workforces to demonstrate commitment toward strategic growth. On the back of co-innovation, sustainable solutions and practices, and service excellence, their valuation has surged past $94 billion.

Since the early days of the fiber and 5G boom, Cyient has embraced next-generation technology to become a world leader in fast, high-quality engineering for telecom and utilities. Their telecom division has more than 60 million hours of experience on fiber-to-the-home (FTTH) projects. “Our company is very progressive from a technology standpoint,” says a former Cyient senior manager of communications for North America. “We’re always looking for better, more efficient ways of doing things.”

Cyient has been working with IKE side by side since the days of IKE 3 more than 6 years ago. Through the rollout of IKE 4 (now just IKE) in 2016, Cyient provided real-world input into the product design process to help hone it into the pole data collection machine it is today. As remembered by a Cyient senior manager, “Their development team came to our location with a prototype, and we were able to tell them what we liked and didn’t like, and they were responsive,” he remembers. “We helped steer them to create a solution that fits our business, and they’ve been a fantastic partner and supplier.”

Widespread deployment of IKE helped Cyient standardize their collection process and empower offshore engineering teams to return deliverables overnight. IKE was their digital height stick that sped up field collection and made for easy digitization of heights of attachment and other pole data in those days. The simple field benefits alone gave Cyient the return they needed for many years.

90+

Devices

2

Advanced Field Dashboards

4

Critical New IKE Office Features

The Challenge

In the world of engineering service providers, scalability becomes more and more difficult as the amount of work increases. For Cyient, the management of capital assets through the ups and downs of projects is a critical factor as they continue to scale. Using the devices as they had been, Cyient had no view into how much the devices were being used and how productive their fielders were being. The lack of visibility presented a challenge as Cyient continued to grow their telecom business and their fleet of IKE’s along with it.

With the prospect of massive scalability in front of them, Cyient looked to IKE for a solution to the management of their devices and the productivity of their fielders. In addition to the device management, Cyient found an opportunity to re-examine their usage of the IKE to meet the expanding needs of their customers and their high expectations of process efficiency.

What Happened

Since the release of IKE 4 in 2016, IKE’s capability has expanded far beyond the digital height stick capabilities that Cyient had been leveraging. In 2021, IKE is providing solutions to customers up and down the value chain from field data collection through pole load analysis and permitting.

A major part of the development came with the release of the next generation of IKE Office, called IKE Office Pro. Developed alongside major partners in telecom, IKE Office Pro contained game-changing workflow enhancements and new features to represent the next wave of IKE innovation.

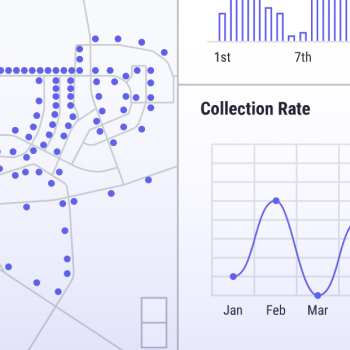

Perhaps the standout feature for Cyient was the newly developed IKE Dashboards. The data visualizations therein allow users to gain new insight into how their projects are performing. With data coming from the IKE Device, Cyient now has access to a field-specific dashboard dedicated to managing devices and fielders including data on:

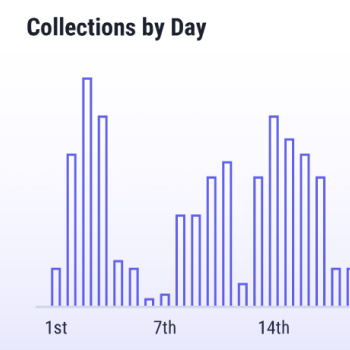

- Device usageShows all poles collected by each device in all of Cyient’s departments within a specified period.

- Fielding ProgressDisplays the fielding progress information, including the total number of poles collected as well as the daily collection rates for each fielder.

By implementing the fielding dashboards, Cyient gained the ability to easily see detailed metrics on field data collection, a piece of their business that was previously lacking clear metrics. They can now use data to improve the usage of devices and the performance of the people using them. As the former senior manager tells it, “It [IKE] helps make new employees efficient in short order as opposed to months of training on traditional data collection methods.” Not only can employees ramp up fast, but they can also continually monitor their collection speed and address performance issues before they affect team productivity.

For a company widely considered one of the best in the world at outsourced engineering, the ability to easily monitor efficiency in driving data from their field teams to their outsourced engineering teams has been invaluable.

Moving beyond the digital height stick

With the adoption of IKE Office Pro, Cyient gained access to more than just dashboards. A suite of new features has allowed them to expand capability and streamline their internal processes as they increase their focus on technology-led transformation of network design, deployment & transformation.

The key features for Cyient have been:

- Data Roundtrip Cyient can now pre-load IKE’s with data such as pole locations and existing data by simply uploading a spreadsheet in IKE Office. The pre-loaded data allows fielders to manage their routes better and quickly find the poles they need to collect. Once they collect data in the field, the new data takes a round trip back to IKE Office, where the pole record is updated.

- Vector Representations When a point-to-point measurement of a span or anchor lead length is taken in the field, it is represented as a vector line in IKE Office. Unlike the traditional method of checking the numerical data, the visual representation allows Cyient to review span and anchor measurements significantly faster.

- Collection Linking Creates a vector line between two collections (poles) based on a high accuracy location measurement. The link gives a span a length and bearing while eliminating the need to take certain span shots in the field.

- Reverse Geocoding Back office employees can generate the nearest address to a pole based on location, streamlining billing and reporting.

Cyient continues to be a leader in the adoption and large-scale deployment of IKE as they have always been. Though now, they can meet the opportunity to scale with full knowledge of their IKE’s performance.

Empowered by fielding dashboards and advanced new features, Cyient fielders consistently collect high-quality data using more than eighty IKE Devices. Meanwhile, managers and executives can keep a close eye on productivity and a consistent flow of data with IKE Dashboards. From there, the back-office teams can consistently leverage next-generation IKE Office Pro features like data round trip for overnight analysis. The result? An optimized workflow to match Cyient’s 24% growth in order intake in 2021. With continued innovation using IKE, Cyient firmly positions themselves as a leader in engineering a more connected future.