The PoleOS™ Company

Safety and speed in pole data collection

Data collection is at the heart of building and maintaining our power and communication infrastructure. But for decades, field teams have faced the same challenges: safety hazards, error-prone manual processes and inefficient workflows. Today, technology is changing the game. In this article, we’ll explore how the IKE Device and IKE Office Pro are reshaping fielding – making it safer, faster and more reliable.

Risks and roadblocks with the traditional approach to pole data collection

If you’ve ever worked in the field, you know the drill: hauling out a Hastings stick, juggling paper forms, and trying to take accurate measurements while traffic whizzes by or a dog barks from the next yard. These methods, while tried and true, come with serious downsides:

- Safety hazards: Measuring midspans over busy roads, navigating dense vegetation, or entering unfamiliar properties, or entering unfamiliar properties exposes fielders to real risks-traffic accidents, animal encounters, and environmental hazards.

- Physical demands: Carrying heavy, bulky equipment all day is exhausting and can lead to injuries.

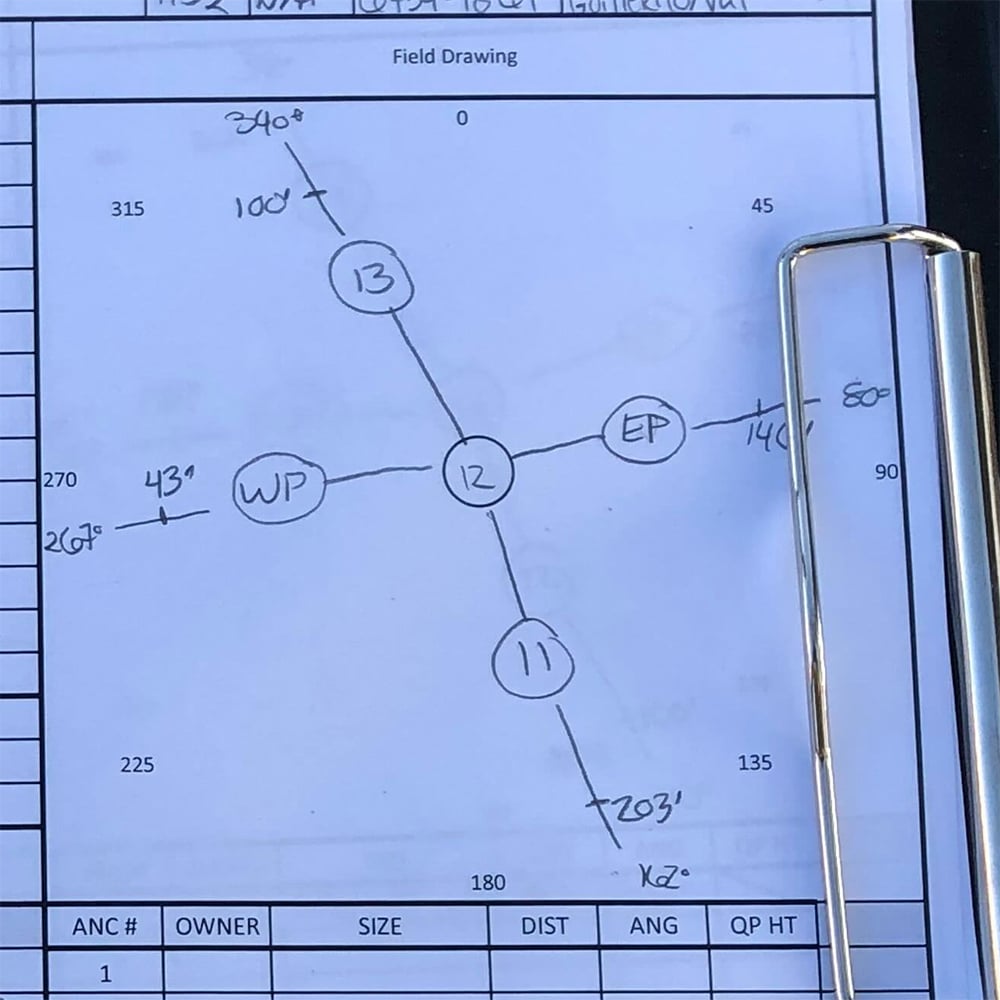

- Inefficiency: Manual note-taking, limited stick reach, and the need for two-person crews slow down projects. Errors in handwriting or measurement can mean costly repeat visits.

- Data quality issues: Paper forms and manual sketches are prone to mistakes and can be hard to verify later, especially when disputes arise.

Field professionals often share stories about near-misses in traffic, equipment mishaps, or lost notes that forced them to revisit sites. These aren’t just anecdotes – they’re symptoms of a system in need of innovation.

Enter IKE: A modern solution

The IKE Device, paired with IKE Office Pro, addresses these pain points head-on. Here’s how:

1. Safety first

With IKE, field technicians can collect midspan measurements and visible pole data from a safe distance. The Device’s integrated camera and laser tools allow accurate measurement from the sidewalk or road shoulder, helping reduce risk and streamline fieldwork.

When the entire pole is visible, even from a distance, technicians can often complete the capture without needing direct access. However, if the base is obscured by vegetation or behind locked fences, additional access may be required. When the base of the pole is physically accessible, an offset stick can assist.

2. Speed and efficiency

With IKE, what once took a two-person crew an entire day can now be accomplished by one person in a fraction of the time. Fielders can collect data on 80-100 poles per day, compared to the traditional 12-20. Digital workflows eliminate the need for manual sketches and notes, allowing fielders to focus on collecting high-quality data and staying aware of their surroundings.

3. Data quality and verifiability

Every IKE measurement and annotation is tied to high-resolution, laser-calibrated photographs. This creates a permanent, verifiable digital record-essential for audits, permitting, or resolving disputes. Back-office teams can review and quality-check data without setting foot in the field.

IKE Office Pro is designed to efficiently handle vertical separation measurements and other specialized needs, moving tedious calculations from the field to the back office. This not only saves time and promotes field safety but also improves accuracy and consistency.

4. Seamless back-office integration

Once field data is collected, it’s uploaded to IKE Office Pro. Here, teams and authorized third parties can:

- Review images and measurements

- Annotate and validate data

- Use data to conduct pole loading analysis

- Generate reports and share with stakeholders

This reduces errors, streamlines workflows, and ensures everyone is working from the same accurate information. IKE Office Pro offers direct integration with PLA applications, along with API and export options, at no additional cost (unlike many of our competitors).

Benefits of advanced fielding and pole data management solutions

- Safety: Fewer accidents and injuries mean lower insurance costs and greater peace of mind for field crews.

- Productivity: Projects move faster, with smaller field crews, fewer site visits and less downtime.

- Data quality: Verifiable digital records reduce disputes, speed up permitting, and improve overall project outcomes.

Conclusion

The days of hazardous, slow, and error-prone pole data collection are numbered. With tools like IKE Device and IKE Office Pro, field teams can work safer, faster, and smarter-delivering better results for their organizations and the communities they serve.

Interested in seeing IKE in action? Reach out for a tailored demo and discover how you can transform your fielding operations today.

Request a Demo

Spencer Hankin is a Senior GIS Manager for ikeGPS. He has worked in every aspect of OSP aerial engineering including fielding poles in remote areas, building PLAs, managing field teams, and overseeing fiber design projects from start to finish as a lead OSP engineer. He holds an undergraduate degree in Geology from the University of Colorado and an MBA from the University of Redlands with a concentration in Location Analytics.

The latest from the IKE Wire

Celebrating 2025 Achievements in Field Data Collection: Luck Grove Leader in Utility Pole Collection

Utility engineering experts top 220,000 collections in 2025 As we close out 2025, the...

Read MorePole Attachment Tips for Successful BEAD Deployments

Four tips to reduce friction in attachment processes The Broadband Equity Access and ...

Read MoreUnderstanding the NESC rules for streetlights in the Communication Worker Safety Zone

In an earlier blog post, we explored the Communication Worker Safety Zone – its...

Read MoreSubscribe to the IKE Wire

Get the latest insights on data acquisition and structural analysis from the ikeGPS experts.