The PoleOS™ Company

A guide for broadband network expansion: Overcoming bottlenecks in the pole attachment process

The expansion of broadband infrastructure is vital for modern communication and economic development, creating opportunities in both urban and rural areas. As the need for data and image transmission grows, so does the demand for high-speed internet. Governments, utilities, and private entities are prioritizing broadband expansion to meet this demand. However, constructing new networks or expanding existing ones presents significant challenges, particularly in navigating the complex pole attachment process required to access existing electric utility poles.

The pole attachment process, which governs the placement of communication equipment on existing utility poles, presents multiple, significant bottlenecks that can hinder broadband deployment. These bottlenecks arise from a confluence of factors, including protracted timelines, inconsistent data quality, complex regulatory landscapes, and insufficient collaboration among stakeholders. The Federal Communications Commission (FCC) has acknowledged1 that disputes over pole attachments can significantly delay broadband deployment. They state in the report, “Pole-owner refusals to provide access to pole-related information have a material and adverse impact on broadband deployment.” Additionally, the FCC highlights that the delays associated with pole attachment disputes and the costs of pole replacements can inhibit broadband expansion, particularly in underserved areas. These delays often arise because of disputes over cost responsibilities or transparency in pole conditions.

To address these delays, the FCC has introduced measures such as a Rapid Broadband Assessment Team (RBAT), which aims to resolve disputes faster by engaging stakeholders, facilitating mediation, and using expedited processes for complaints. This demonstrates that unresolved disputes about costs, timelines, or access to poles can create bottlenecks that hinder the broader goal of connecting unserved and underserved areas.

These challenges translate to increased project costs, missed deadlines, and ultimately, slower broadband rollout. In some cases, disputes over pole attachment costs have added months to broadband deployment timelines, particularly in rural areas. In Virginia2, efforts to expand broadband have encountered substantial delays due to challenges in preparing utility poles for high-speed fiber. These setbacks threaten the timely utilization of federal funding allocated for the project.

The delays in attachment projects reduce the success of programs such as BEAD (Broadband Equity, Access, and Deployment). BEAD is a federal initiative established under the Infrastructure Investment and Jobs Act (IIJA) to allocate $42.45 billion for expanding high-speed internet access across the United States. The program’s goals are to ensure that unserved and underserved communities, particularly rural and economically disadvantaged areas, receive reliable and affordable broadband connectivity. Unserved and underserved areas are disproportionately affected by pole attachment delays. These communities already face economic and geographic barriers to broadband access. Further delays exacerbate the digital divide and undermine the program’s mission of ensuring equitable access.

This white paper provides a comprehensive analysis of these challenges and attempts to synthesize insights and practical remedies to streamline pole attachment processes, drawing on expert discussions, industry best practices, and relevant publications. By implementing strategic planning, leveraging investments in advanced technology, and fostering improved communication, stakeholders can overcome these obstacles and accelerate broadband deployment.

The challenges in pole attachment

Lengthy approval timelines

Approvals for pole attachment applications frequently extend to a year or more. This delay stems from limited staffing, high application volumes, and inefficient workflows. Protracted approval cycles can jeopardize deployment timelines, inflate costs, and create frustration for stakeholders.

The process of securing necessary permits and agreements from pole owners can be exceptionally slow, often stretching to a year or more. This is particularly prevalent in regions characterized by stringent local regulations, limited staffing resources at permitting agencies, or a high volume of attachment requests. These prolonged timelines have a cascading effect, jeopardizing project deadlines, increasing carrying costs for equipment and personnel, and delaying crucial broadband service delivery to communities. The unpredictable nature of these timelines also makes accurate project budgeting and forecasting difficult.

Permitting delays

In one county in rural Virginia3, the utility pole owner is taking on average 234 days to process a permit application (FCC rules state that pole owners have 165 days to process applications). Cited reasons for the delay include lack of engineering resources and supply chain issues on necessary equipment such as transformers, paired with the need for significant make-ready work in rural areas.

Data accuracy and accessibility

Limited access to critical, accurate, and complete field data is essential for effective structural analysis and decision-making. Data inconsistencies—such as incorrect pole heights, span measurements, and clearance standards—can result in rework, delays, and disputes. States governed by the FCC have a 45-day shot clock to process the application, survey, and deliver the make-ready required for the applicant to attach their devices. A 45-day time frame for large applications can be daunting, due to the engineering analysis required to determine what, if any, work needs to be done for the third party to attach without any violations.

Accurate and reliable data is the cornerstone of successful pole attachment projects. Inconsistent, incomplete, or outdated data frequently leads to costly rework, miscalculations in pole loading analyses (determining if a pole can safely support new attachments), and inaccurate project cost estimations.

Specific data quality issues include inaccurate pole height measurements, incorrect span calculations (distances between poles), misapplication of clearance standards (vertical and horizontal distances required between wires and other objects), and discrepancies in existing attachment records. These data discrepancies can lead to field crews discovering unexpected issues, requiring costly and time-consuming changes to project plans.

Regulatory hurdles

Regulatory challenges abound in the pole attachment process. Broadband deployments must navigate a complex regulatory landscape, including National Electrical Safety Code® (NESC®) requirements and additional local regulations. Differences in standards, such as unique clearance requirements on state roads, often complicate planning and execution. For its part, the FCC has attempted to streamline its attachment rules to promote broadband deployment.4

Pole attachments are subject to a complex web of regulations at the local, state, and national levels. National safety codes, such as the NESC, establish baseline requirements for pole attachments, covering aspects like clearances, grounding, and structural integrity. However, local jurisdictions often impose additional requirements, such as increased clearance standards on state roads or specific permitting processes for attachments in historical districts. These varying local regulations are often not adequately accounted for in initial project planning, leading to conflicts during project execution, unexpected delays, and potential legal disputes. Understanding and navigating this complex regulatory landscape is crucial for avoiding costly setbacks.

Varying regulations

One broadband provider in California faced delays because local regulations in certain jurisdictions required additional clearance for state highway crossings, conflicting with FCC standards. This misalignment forced the provider to redo designs and resubmit applications, delaying deployment by six months.

Cost disputes

Disputes between pole owners and attachers over make-ready arise when inaccurate data leads to unnecessary work or when pole owners challenge submitted calculations. A fact sheet by the National Cable & Telecommunications Association (NCTA)5 highlights that electric cooperatives and municipalities often impose unregulated, excessive pole attachment rates. Such disputes strain relationships and further delay projects.

To clarify and define the cost responsibilities, the FCC’s Fourth Report and Order and Declaratory Ruling aim to streamline broadband infrastructure deployment by:

- Expanding the definition of “red-tagged poles”: This clarifies that utilities cannot charge attachers for pole replacements when those poles are already scheduled for replacement due to reasons unrelated to the new attachment.

- Clarifying cost-sharing responsibilities: The ruling provides further examples of situations where utilities must share the cost of pole replacement, ensuring fair cost allocation for attachers.

- Improving access to information: Attachers are now granted clearer rights to access information regarding utility easements, aiding in their planning and deployment efforts.

- Streamlining the pole attachment process: The FCC mandates that pole owners adhere to specific timelines for processing attachment requests for up to 3,000 poles, even for larger projects.

- Expediting complaint resolution: A new intra-agency process has been implemented to accelerate the resolution of pole access complaints filed with the FCC.

- Enhancing transparency: Increased record retention and disclosure requirements for pole owners provide attachers with more information needed to plan their broadband deployments effectively.

Prohibitive costs and fees

In West Virginia, disputes continue between power companies and internet providers over allocating pole attachment costs. Costs for attaching fiber to existing poles or replacing aging poles to accommodate fiber are estimated to range from $600 to $6,000 per pole, whereas for example, one provider budgeted about $300 a pole for these costs.6

Breakdowns in communication and collaboration

Effective communication and collaboration are essential for streamlining the pole attachment process. However, a lack of coordination between network operators (those installing the equipment), engineering firms (responsible for design and analysis), and pole owners (typically utility companies) often can create significant bottlenecks. Miscommunication and a lack of shared data lead to redundant field checks, inaccurate make-ready estimates (the cost of preparing a pole for new attachments), and strained relationships among stakeholders. These communication breakdowns can result in duplicated effort, increased costs, and project delays.

Utilities also sometimes fail to maintain adequate lists of approved contractors, forcing broadband providers to rely solely on a select few, which can lead to delays. Although FCC rules require utilities to keep a “reasonably sufficient” list of contractors authorized to perform make-ready tasks, some broadband providers contend that utilities do not comply with this requirement.7

Remedies to address bottlenecks

Organizations seeking to optimize the pole attachment process must adopt a holistic approach to technology implementation. This involves selecting and integrating technologies that facilitate cross-functional collaboration and data sharing across all project stakeholders. Advanced software platforms enable teams to centralize data management, integrate disparate processes, and streamline communication workflows, creating a more efficient and transparent process.

Intelligent automation

Automation and artificial intelligence (AI) offer significant opportunities to enhance efficiency and accuracy in the pole attachment process. For example:

- AI-driven tools can automate complex tasks such as pole loading analysis, significantly reducing manual effort and minimizing the risk of human error. AI algorithms can analyze large datasets of pole characteristics and attachment specifications to quickly determine if a pole can safely accommodate new equipment.

- Automation platforms streamline administrative tasks such as application submissions, automated notifications to stakeholders regarding project updates, and comprehensive project tracking. This reduces paperwork, minimizes manual data entry, and ensures that all stakeholders are kept informed of project progress.

Data integrity and management

High-quality field data is crucial for accurate planning and analysis. Utilizing advanced data collection tools, such as GPS devices with real-time kinematic8 (RTK) technology, laser rangefinders, and 3D scanners, ensures precise measurements of pole locations, span lengths, and existing attachments. RTK technology, in particular, offers centimeter-level accuracy, significantly reducing the need for rework and expediting the overall process.

For large-scale projects, importing data in bulk—rather than gathering it incrementally—saves time and resources. Automated processes can integrate existing data from utilities, National Joint Utilities Notification System (NJUNS)9 tickets, and engineering firms, ensuring completeness and accuracy.

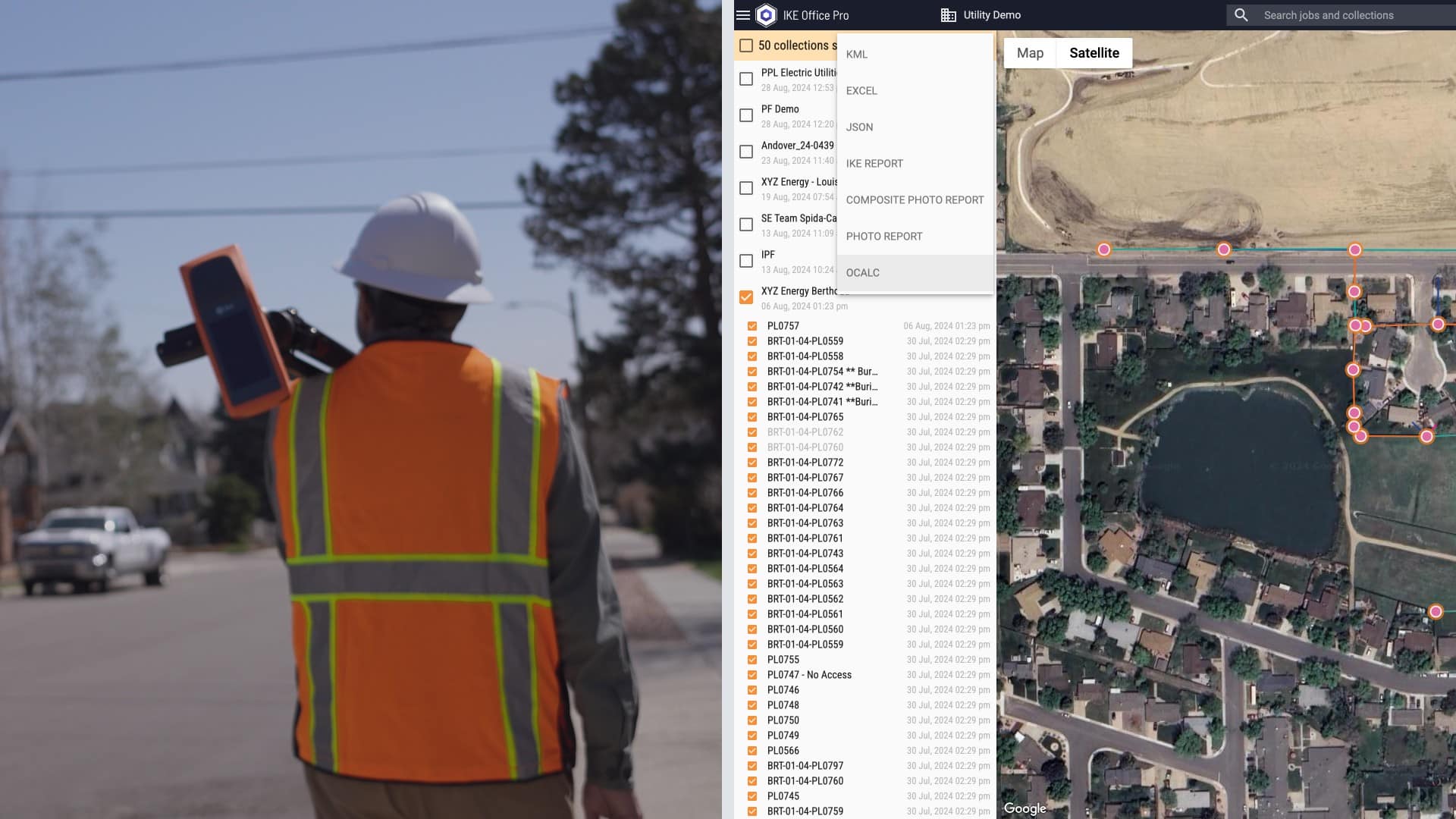

IKE Office Pro’s dashboards transform raw data into actionable insights, enabling better decisions and providing a clear view of project status.

Establishing centralized data management platforms provides a unified and accessible repository for all collected field data. This centralized approach enables stakeholders to access consistent, verified, and up-to-date information, fostering trust and reducing redundancies caused by conflicting or outdated data.

Alignment with pole owner standards and requirements

As with any project, engaging key stakeholders, such as pole owners early in the project lifecycle is critical for establishing clear expectations and fostering a collaborative environment. Early engagement ensures alignment on project requirements, data-sharing protocols, realistic project timelines, and helps to mitigate potential conflicts and promotes a cooperative working relationship.

Open and transparent data sharing with pole owners builds trust and reduces the likelihood of redundant field checks. Implementing collaborative platforms that facilitate seamless data exchange improves decision-making processes, reduces misunderstandings, and fosters a more efficient and collaborative workflow.

A thorough understanding of the NESC and other relevant industry standards, as well as local jurisdictional requirements, is essential for ensuring safe and compliant pole attachments. This knowledge empowers anyone planning on making an attachment to self-perform pole loading analyses effectively and streamlines make-ready work, minimizing potential conflicts with pole owners and avoiding costly rework.

Investing in comprehensive training programs on NESC, OSHA safety standards, and local regulations empowers teams to make informed decisions and ensures consistency in the application of these standards. This emphasis on education leads to better compliance, reduces the risk of safety incidents, and minimizes project delays caused by non-compliance.

By fostering a culture of open communication and collaboration, utilities, attachers, and other stakeholders can work together more effectively to navigate the pole attachment process, accelerate broadband deployment, and ensure the safe and reliable operation of both telecommunications and utility infrastructure.

The importance of structural analysis

Accurate pole loading analysis is paramount for ensuring the safety and structural integrity of utility poles. Pole loading analysis determines if a pole can safely support the weight and tension of new attachments, considering existing attachments, environmental factors (wind, ice), and the pole’s material and condition. Pole loading analysis models must be based on precise and up-to-date data to be reliable because errors in these models can have devastating consequences:

- Unnecessary make-ready work: Overly conservative models, based on inaccurate data, can lead to unnecessary and costly make-ready work, such as pole replacements or reinforcements, even when the existing pole is structurally sound.

- Unsafe attachments: Conversely, inaccurate models that underestimate the load capacity of a pole can result in unsafe attachments, posing a risk of pole failure, downed wires, and potential safety hazards for workers and the public.

- Increased project costs: Both unnecessary make-ready work and the consequences of unsafe attachments contribute to significantly increased project costs, delays, and potential legal liabilities.

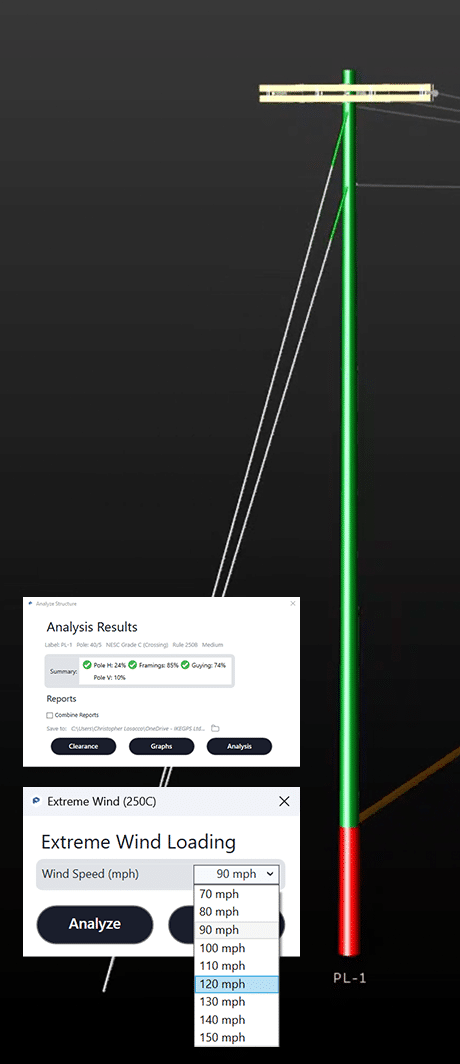

IKE PoleForeman’s easy-to-use interface simplifies the joint-use process and even lets you load in specific operating companies’ standards.

Automation platforms offer significant advantages in streamlining and improving the accuracy of pole loading calculations:

- Using accurate field data: Automated systems can directly integrate with field data collection tools, ensuring that pole loading models are built using the most current and accurate measurements of pole characteristics, existing attachments, and environmental conditions.

- Reducing manual input errors: By automating data transfer and calculations, these platforms minimize the risk of human error associated with manual data entry and complex calculations.

- Integrating with major pole loading software: Seamless integration with industry-standard pole loading software ensures compatibility and streamlines the submission of analysis results to pole owners and regulatory agencies.

One-Touch-Make-Ready

Collaboration with pole owners is crucial for obtaining accurate data on existing conductors, tensions, and other relevant parameters. An example is One-Touch Make-Ready (OTMR) is a streamlined process for preparing utility poles to accommodate new broadband or telecommunications attachments. It is designed to accelerate the deployment of broadband infrastructure, especially in underserved areas, by reducing delays and costs associated with the traditional multi-step process. The Federal Communications Commission (FCC) adopted OTMR rules in 2018 as part of its effort to accelerate broadband deployment. These rules apply to most poles owned by utilities in the United States, with exceptions for poles owned by municipalities and cooperative utilities. OTMR has become a critical tool in programs like the BEAD program, where timely pole access is essential for achieving universal broadband deployment goals.

A proactive approach to data sharing and collaboration such as OTMR reduces the likelihood of disputes over analysis results and minimizes delays caused by data discrepancies. Sharing analysis results with pole owners also fosters transparency and builds trust.

The importance of project management

Leveraging project management tools with built-in automation features can significantly enhance efficiency and organization throughout the pole attachment process:

- Sending automated notifications: Automated notifications for application updates, approvals, and other key milestones keep all stakeholders informed of project progress.

- Tracking project progress: These tools provide comprehensive tracking of project progress across numerous poles, allowing project managers to identify potential bottlenecks and proactively address issues.

- Providing real-time visibility: Real-time dashboards and reporting features provide stakeholders with clear visibility into project milestones, timelines, and budgets, enhancing transparency and accountability.

Regular touchpoint meetings with all stakeholders are essential for maintaining alignment on project priorities, timelines, and potential challenges. These meetings provide a forum for open communication, proactive problem-solving, and collaborative decision-making. Consistent communication helps to prevent misunderstandings and maintain project momentum.

Utilizing single-source platforms that integrate data collection, analysis, and reporting creates a seamless and efficient workflow from field to finish. These integrated tools enhance transparency and accountability throughout the entire project lifecycle, minimizing data silos and facilitating better communication among stakeholders.

The benefits of streamlined processes

Streamlined pole attachment processes translate directly to significant cost and time savings through:

- Reduced rework: Accurate data, automated analysis, and effective communication minimize the need for costly and time-consuming rework due to data errors or miscommunication.

- Expedited approvals: Efficient processes and clear communication facilitate faster approvals from pole owners and regulatory agencies, reducing project delays.

- Optimized resource allocation: Streamlined workflows and improved project management enable organizations to optimize resource allocation, ensuring that personnel and equipment are deployed efficiently.

Transparent and collaborative practices enhance trust and foster strong, long-term partnerships among stakeholders. Open communication, shared data, and proactive problem-solving create a more positive and collaborative working environment.

Accurate data, adherence to industry standards, and effective communication contribute to safer and more compliant pole attachments. Minimizing errors in pole loading analysis and ensuring compliance with NESC and other relevant regulations reduces the risk of safety incidents and potential legal liabilities.

How IKE can help

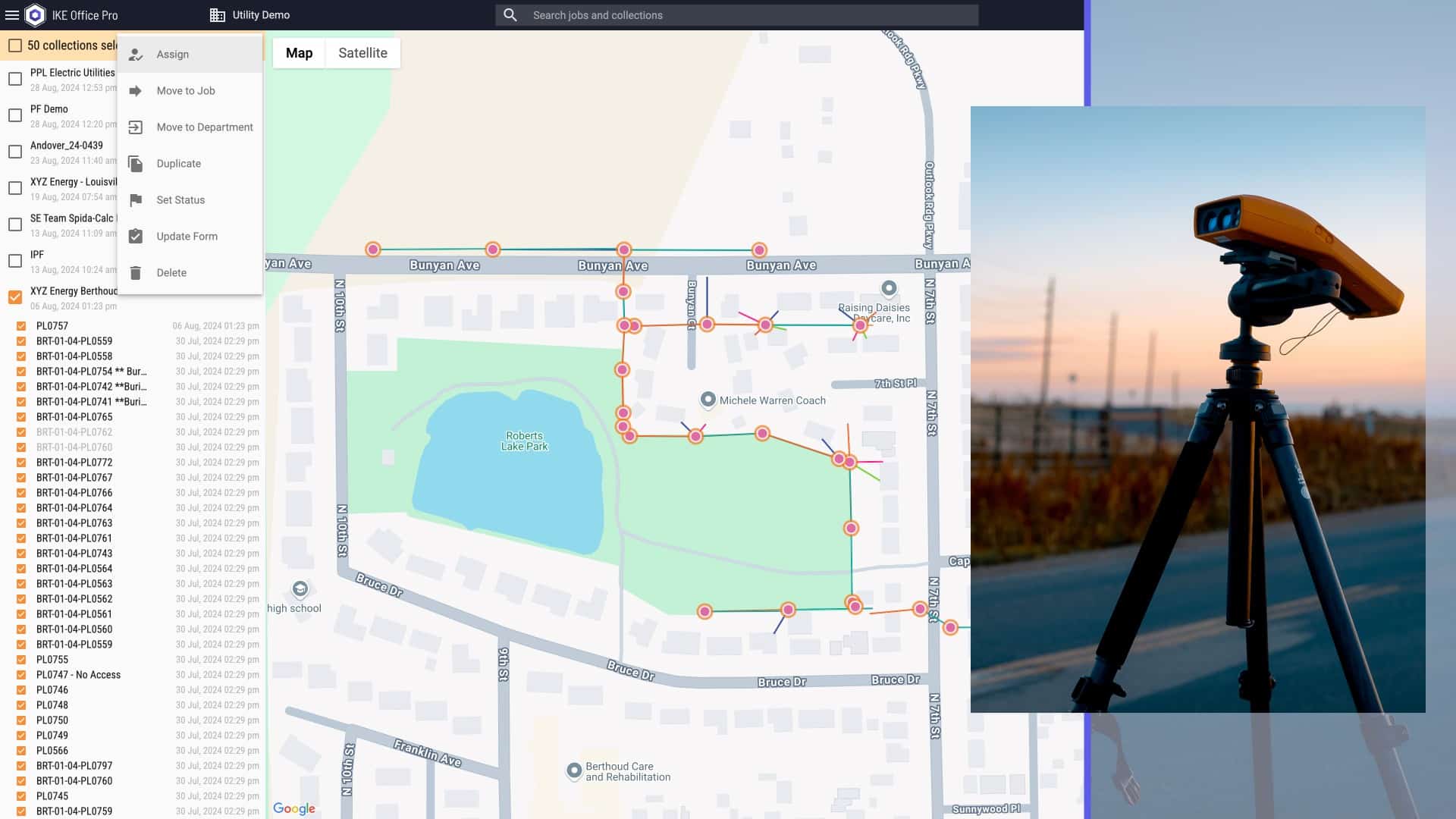

Pole data management: IKE Office Pro

IKE’s cloud-based software enables you to measure and manage pole records and serves as a centralized, accessible platform for collaboration between fielding, back office, and third parties. Through reporting, API’s, and an array of export features, IKE Office Pro integrates field data with downstream processes and applications.

Pole loading analysis: IKE PoleForeman

IKE PoleForeman has been the industry standard for delivering accurate and reliable pole loading analysis for nearly two decades. Build reliable structural models, measure span clearances, and ensure NESC compliance on an easy-to-use interface.

Process automation: IKE Insight

Automate manual tasks and gain actionable insights by applying AI and predictive analytics to bulk data and imagery.

Training & education: IKE’s NESC classes

IKE’s training offerings take the complex and often hard-to-understand Code and transform it into practical, relatable information that can be applied to daily utility work. Classes are presented in-person or online.

In closing

Addressing bottlenecks in the pole attachment process requires a strategic and multifaceted approach that encompasses technology adoption, data accuracy, collaboration, and compliance. By implementing innovative tools, prioritizing high-quality data collection, and fostering open communication among stakeholders, organizations can significantly streamline deployments and meet challenging project deadlines. These optimized practices not only enhance efficiency and reduce costs but also strengthen stakeholder relationships, improve safety, and position companies as leaders in the increasingly competitive broadband landscape. Embracing these strategies is essential for accelerating broadband deployment and ensuring that communities have access to the critical connectivity they need.

References

- FCC Declaratory Ruling and Fourth Report and Order (FCC-18-111).

Accessed at: https://docs.fcc.gov/public/attachments/FCC-23-109A1.pdf - “Virginia is trying to get broadband to 162,000 locations without it.”

Accessed at: https://cardinalnews.org/2024/01/03/as-broadband-funding-flows-expansion-projects-hit-a-low-tech-snag-utility-poles/ - “Virginia is trying to get broadband to 162,000 locations without it. Old utility poles may get in the way.”

Accessed at: https://cardinalnews.org/2024/01/03/as-broadband-funding-flows-expansion-projects-hit-a-low-tech-snag-utility-poles/ - Maria T. Browne and John C. Nelson Jr., “FCC Reforms Pole Attachment Rules to Promote Broadband Deployment”, December 15, 2023.

Accessed at: https://www.dwt.com/blogs/broadband-advisor/2023/12/fcc-reforms-pole-attachment-rules/ - NCTA, “Close Pole Rate Loopholes to Promote Rural Broadband Investment and Deployment.”

Accessed at: https://www.ncta.com/sites/default/files/2020-10/pole_attachments_fact_sheet.pdf - “West Virginia risks losing out on $1 billion as internet and utility companies fight over broadband expansion costs.”

Accessed at: https://mountainstatespotlight.org/2024/11/11/broadband-pole-attachment-fight/ - “Altice USA Wants FCC to Address Utility Delays in Pole Attachments.”

Accessed at: https://broadbandbreakfast.com/altice-usa-wants-fcc-to-address-utility-delays-in-pole-attachments/ - Real-time kinematic positioning (RTK) is the application of surveying to correct for common errors in current satellite navigation (GNSS) systems.

- NJUNS is a web-based system developed to improve joint use communication, and will actively participate during the term of service, by entering field information into the NJUNS system within the times required by the system.

About IKE

We’re ikeGPS, the PoleOS™ Company. We help electric utilities, communications companies, and their engineering providers gain actionable insights on overhead infrastructure. Our data acquisition and analysis solutions transform how to design, construct, and inspect overhead assets.

IKE’s suite of solutions have wide-ranging use cases including pole inspections, field data collection, pole loading analysis, make-ready engineering, network-level assessments, and permitting. They enable dramatic productivity gains, reduce risk, and optimize investments, while upholding safety standards.

With two decades of industry expertise, IKE has become the standard for eight of the 10 largest investor-owned electric utilities in North America.

Driven by our commitment to essential infrastructure and to the success and well-being of those who manage it, IKE innovates for the next generation of power networks.

Table of contents

- The challenges in pole attachment

- Remedies to address bottlenecks

- How IKE can help

- In closing

Learn how IKE helps communications companies accelerate broadband deployments

The latest from IKE

Four ways to streamline the broadband deployment process

In today's competitive broadband landscape, communications companies face many challenges to efficient network expansion. Lengthy approval processes, limited access to critical data, regulatory hurdles, and...

Read NowToth & Associates speeds up pole data collection and accuracy

Toth & Associates achieved the scale needed to take on and successfully deliver large (50,000+) pole projects by making the IKE Device integral to their...

Read NowThe common enemy in joint-use projects: Inefficient workflows

Cloud-based workflows can be a savior for all parties involved The race to expand broadband access across the country relies heavily on the joint-use process,...

Read Now