The PoleOS™ Company

The Challenge

CHR needed to expand its capabilities in field data collection, pole load analysis, and make-ready engineering to provide cutting-edge solutions to its customers.

The Outcome

CHR partnered with IKE to optimize field data collection using the IKE Device. Then, they used IKE Office and IKE Analyze to expand their pole loading capability and automate make-ready engineering as a productized solution for their customers.

IKE 4 was released in July 2016. I started working as an account manager at IKE two weeks later. A few months after that, we closed a deal with a company called CHR Solutions and their VP of OSP engineering, Bob Bartz. So began a transformative relationship between IKE and CHR which has seen CHR continuously innovate using IKE as an evolutionary technology suite. The partnership has allowed CHR to expand its portfolio of services, increase its bottom line, and create meaningful impacts in community connectivity amid a global crisis.

One look at their website will tell you that CHR has over 75 years of experience supporting communications service providers on projects, including audits and fiber network deployment. Over all those years, CHR has excelled through a culture of innovation and ingenuity. They can solve problems for their customers in ways few others could. As Bartz tells it, “IKE has allowed us to expand from being an engineering service provider to being a solution provider.”

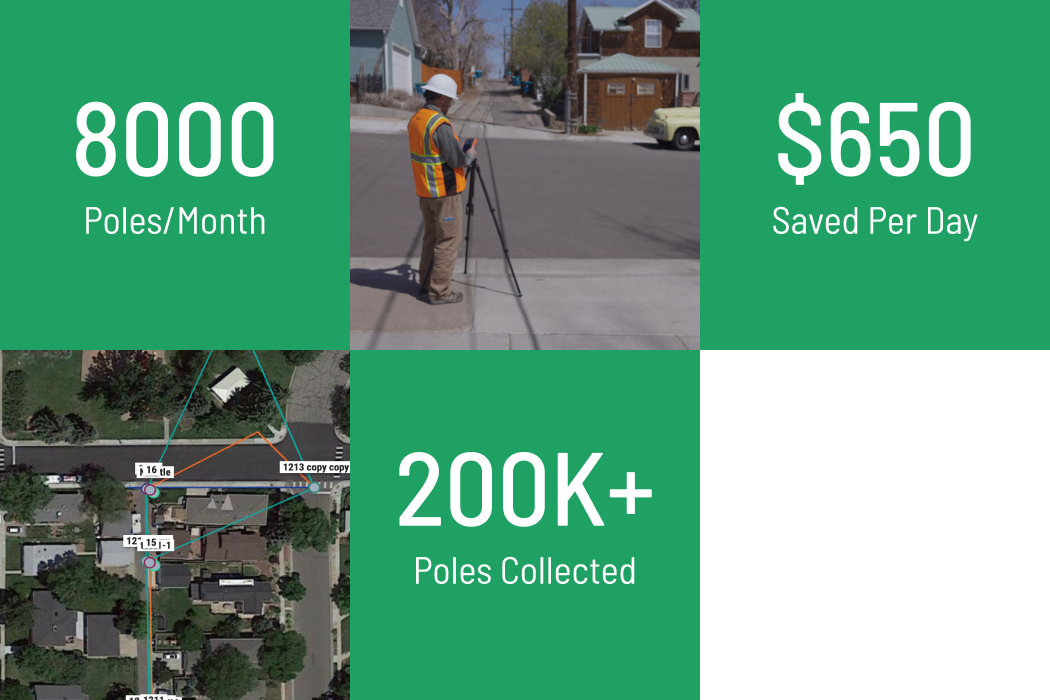

Starting in the field

When CHR first contacted IKE, they needed to find a better way to collect pole data for fiber network projects nationwide. They had teams of two collecting heights of attachments, span lengths, pole tags, and mid-span heights with nothing but a stick and a rangefinder. IKE worked with CHR to determine that if they could go from two-man teams collecting 110 poles a day with sticks to one-man teams collecting 150 with IKE, they would cut crew costs by more than $650 a day. Knowing that, a fleet of IKE Devices became an easy purchasing decision as CHR expanded their operation into new markets and project types.

Scaling up

A major part of that growth came in 2020 amid the covid-19 pandemic. The worldwide shift to remote work took the problem of fiber and broadband access from problematic to critical. Business, education, and health became more dependent on internet connectivity than ever. Schools were closed, telehealth was imperative, and yet, the connectivity wasn’t where it needed to be for many Americans. Hundreds of millions of dollars were being invested in full-service fiber and broadband projects in an effort to solve the problem. A huge portion of it was coming from communication service providers for whom CHR had long performed data collection and audits. The need to expand their capabilities in pole load analysis (PLA) and make ready engineering (MRE) became overwhelmingly clear.

In an evolving market that maintains an emphasis on quality yet screams for faster speed to market, the question became: How does CHR make PLA and MRE service into a high-value product for their customers while maintaining that speed?

Part of the answer was already in their fielder’s hands in the form of a distinct orange device. The extension of that device that answered the question came in the form of the deliverables coming out of IKE Office.

Speed of collection and processing is where CHR started with IKE. The quality of deliverables allowed them to scale up to provide complex solutions for new and existing customers amid the influx of new work. IKE deliverables allow CHR to provide their customers with interactive maps of their networks where they can see pole data, images, MRE, permitting status, and more with a single click. Bartz says, “Without question, IKE’s deliverable is top shelf. They [CHR’s customers] don’t know how they lived without it.”

For CHR, success comes from creating a superior customer experience (CX) using innovation. IKE has long worked with CHR to open new avenues to improve that CX and the deliverables needed for it while reducing the time needed to create them.

Automating MRE

Make-ready engineering is one of the hard parts of attaching new equipment to poles. It helps maintain safety and compliance but has historically required deep expertise and time that is costly for the company to complete. To solve that problem, IKE collaborated with CHR to create an automated make-ready engineering tool that allows people like Dustin Heath, their Director, Engineering Operations to solve more complex problems for their customers without needing to employ additional Make Ready focused engineers. Heath explains it by saying: “IKE lowers the entry-level for success” Heath and his team can quickly complete make-ready engineering according to NESC code without requiring the deep expertise needed to do it manually. The whole MRE process created using IKE can be completed and ready for delivery in a matter of a few minutes after the data is uploaded from the device.

Expanding PLA Capability

The sporadic nature of how MRE and PLA work is doled out makes it financially very difficult to staff a team of full-time in-house professional engineers to do that work at scale. For years, CHR didn’t bid on large projects that required them to complete MRE and PLA. Having addressed the MRE side of that problem, CHR also needed an avenue for even more varied PLA work. IKE’s analysis service, IKE Analyze, provided it.

CHR leverages its well-practiced data collection team to collect the data and upload it to IKE Office. Then, IKE completes pole load analysis in their software of choice and can provide make-ready recommendations to streamline the MRE process. IKE Analyze allows CHR to deliver robust pole load analysis in the client’s software of choice. So, CHR can maintain a large engineering team focused on higher-value tasks without needing to dedicate any personnel to intermittent yet highly specialized pole load analysis.

Conclusion

Backed by the power of automated MRE and IKE Analyze, CHR won a bid for a 3,000-mile fiber deployment that requires significant PLA and MRE. Up to that point, they would have been hard-pressed to bid on that type of work at that volume. Since then, they’ve expanded the work nationwide and collect up to 8,000 poles a month. They have well over 200,000 poles in their IKE Office account, a huge portion of which have been delivered to happy customers.

Of the evolution of their business, Bartz said: “CHR is on the cutting edge of the new engineering model. IKE has been a huge player in showing the value of that model.” Through the productization of top-notch deliverables using IKE, CHR has defined a cutting-edge customer experience for the clients they work with. As those customers have made more fiber and broadband work available in response to the global situation, CHR has been right there to provide exactly the solution they are looking for at the speed they need.

Without question, IKE’s deliverable is top shelf. They [CHR’s customers] don’t know how they lived without it.

– Bob Bartz, VP of OSP Engineering, CHR

CHR partnered with IKE to optimize field data collection using the IKE Device. Then, they used IKE Office and IKE Analyze to expand their pole loading capability and automate make-ready engineering as a productized solution for their customers.

Get a Demo Today!The latest from the IKE Wire

Celebrating 2025 Achievements in Field Data Collection: Luck Grove Leader in Utility Pole Collection

Utility engineering experts top 220,000 collections in 2025 As we close out 2025, the...

Read MorePole Attachment Tips for Successful BEAD Deployments

Four tips to reduce friction in attachment processes The Broadband Equity Access and ...

Read MoreUnderstanding the NESC rules for streetlights in the Communication Worker Safety Zone

In an earlier blog post, we explored the Communication Worker Safety Zone – its...

Read MoreSubscribe to the IKE Wire

Get the latest insights on data acquisition and structural analysis from the ikeGPS experts.